COMMERCE 2OC3 Study Guide - Final Guide: Vendor-Managed Inventory, Longrun, Comparative Advantage

Supply Chain Management and Analytics

Supply chain management is the management of activities that procure materials and services, transform them in to

intermediate and final products, and deliver them in the distribution system

•

Supply chain analytics are set of quantitative tools used to manage, consisting of data analytics used to understand SC

patterns and performance optimization

•

Supply chain (SC) is a coordinated network of people, organizations, resources that move a product from suppliers to

consumers.

Supply Chain Strategy

Many suppliers strategy based on large supplier base that allows them to compete against one another - no desire to

create long-term relationships

•

Few suppliers strategy based on small supplier base and creating long-term relationships, reducing procurement costs

but increasing the cost of changing partners, and captive risk

•

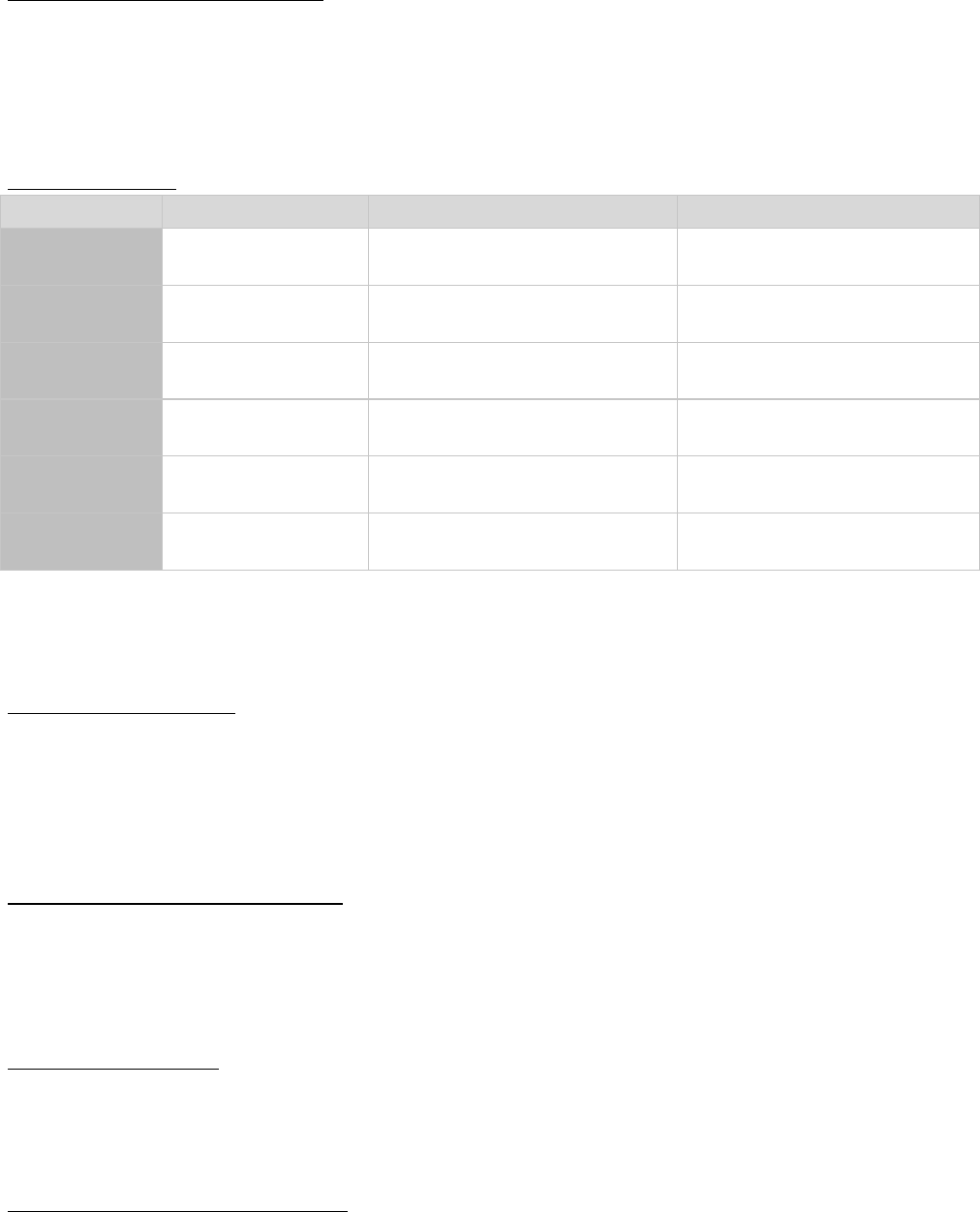

Low cost strategy

Response strategy

Differentiation strategy

Supplier goals

Demand at lowest cost

Quick response to changing demand

to minimize stockouts

Share market research, jointly

develop products

Decisions based on

Cost

Options that provide speed, capacity,

flexibility

Options that enhance product

development

Process

characteristics

High average utilization

Invest in excess capacity and flexible

processes

Use modular processes that lend

themselves to mass customization

Inventory

characteristics

Minimize inventory to

decreases costs

Develop responsive system with

buffer to ensure supply

Minimize inventory to avoid

obsolescence

Lead-time

characteristics

Shorten as long as costs

do not increase

Invest aggressively to reduce

production lead-time

Invest aggressively to reduce

development lead-time

Product-design

characteristics

Maximize performance

and minimize cost

Use product designs that lead to low

setup time and rapid production

Use modular design to postpone

product differentiation

Vertical integration forward and backward and joint ventures

•

Keiretsu networks consisting of company coalitions with share holding between members

•

Virtual companies provide services on-demand

•

Profit sharing where wholesaler and retailer set "integrated optimal retail price" and split profits

○

Revenue sharing where wholesaler and retailer set integrated optimal price and split revenue

○

Supply chain coordination contracts through profit sharing, revenue sharing, buy-back

•

Collaboration in Supply Chain

Reducing risk leads to mitigated disruption in: processes (material, quality, logistics), controls (management,

communications, designs, logistics scheduling), environment (duties, tariffs, security, natural disaster, currency

fluctuations, political issues)

•

Opportunity for personal, SC standard, and environmental ethic violations

•

Reducing SC costs increases profit by the same margin that a greater proportion of additional sales does

•

Supply Chain Risk, Ethics, and Sustainability

Local optimization sees greater fluctuations between optimal demand and supply - slight upturns and downturns are

overcompensated for

•

Incentives push merchandise into SC for sales that have not yet occurred

•

Large lots reduce unit costs but don't reflect actual sales and increase holding costs

•

Managing the Supply Chain

Pull data is accurate sales data that initiates transactions to pull products through the SC, generated by sharing point-

of-sale (POS) data and computer-assisted ordering (CAO)

•

Lot size reduction occurs with aggressive management that emphasizes economical shipments, discounts based on

volume rather than size, and reducing cost of ordering

•

Single-stage control of replication fixes responsibility on a member of the SC for monitoring inventory for the retailer

•

Opportunities in an Integrated Supply Chain

Supply Chain Management & Analytics

February 15, 2018

2:30 PM

Operations Management Page 1

Document Summary

Supply chain (sc) is a coordinated network of people, organizations, resources that move a product from suppliers to consumers. Supply chain management is the management of activities that procure materials and services, transform them in to intermediate and final products, and deliver them in the distribution system. Supply chain analytics are set of quantitative tools used to manage, consisting of data analytics used to understand sc patterns and performance optimization. Demand at lowest cost quick response to changing demand to minimize stockouts. Use modular processes that lend themselves to mass customization. Develop responsive system with buffer to ensure supply. Shorten as long as costs do not increase. Use product designs that lead to low setup time and rapid production. Many suppliers strategy based on large supplier base that allows them to compete against one another - no desire to create long-term relationships.