COMMERCE 2OC3 Lecture Notes - Lecture 16: Scientific Method, Kaizen, Organizational Culture

CHAPTER 16: JIT AND LEAN OPERATIONS

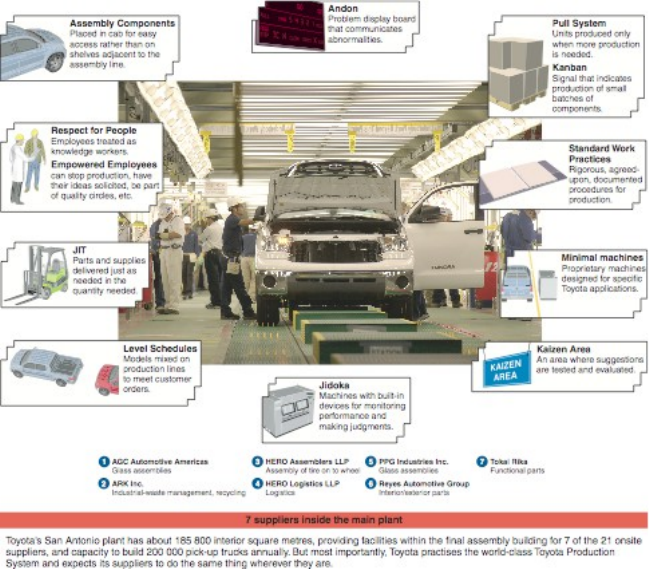

TOYOTA MOTOR CORPORATION

Largest vehicle manufacturer in the world with annual sales of over 9 million vehicles

Success due to two techniques, JIT and TPS

Continual problem solving is central to JIT

Eliminating excess inventory makes problems immediately evident

Central to TPS is employee learning and a continuing effort to produce products under

ideal conditions

Respect for people is fundamental

Small building but high levels of production

Subassemblies are transferred to the assembly line on a JIT basis

High quality and low assembly time per vehicle

JIT/LEAN OPERATIONS

Good production systems require that managers address three issues that are pervasive and

fundamental to operations management: eliminate waste, remove variability, and improve

throughput

JUST-IN-TIME, TPS, AND LEAN OPERATIONS

JIT is a philosophy of continuous and forced problem solving via a focus on throughput

and reduced inventory

TPS emphasizes continuous improvement, respect for people, and standard work

practices

Lean production supplies the customer with their exact wants when the customer wants it

without waste

JIT emphasizes forced problem solving

find more resources at oneclass.com

find more resources at oneclass.com

TPS emphasizes employee learning and empowerment in an assembly-line environment

Lean operations emphasize understanding the customer

ELIMINATE WASTE

Waste is anything that does not add value from the customer point of view

Storage, inspection, delay, waiting in queues, and defective products do not add value

and are 100% waste

OHNO’S SEVEN WASTES

Overproduction

Queues

Transportation

Inventory

Motion

Overprocessing

Defective products

ELIMINATE WASTE

Other resources such as energy, water, and air are often wasted

Efficient, sustainable production minimizes inputs, reduces waste

Traditional “housekeeping” has been expanded to the 5Ss

THE 5S’S

Sort/segregate – when in doubt, throw it out

Simplify/straighten – methods analysis tools

Shine/sweep – clean daily

Standardize – remove variations from processes

Sustain/self-discipline – review work and recognize progress

Two additional Ss

Safety – build in good practices

Support/maintenance – reduce variability and unplanned downtime

JUST-IN-TIME (JIT)

Powerful strategy for improving operations

Materials arrive where they are needed when they are needed

Identifying problems and driving out waste reduces costs and variability and

improves throughput

Requires a meaningful buyer-supplier relationship

JIT & COMPETITIVE ADVANTAGE

find more resources at oneclass.com

find more resources at oneclass.com

Document Summary

Largest vehicle manufacturer in the world with annual sales of over 9 million vehicles. Success due to two techniques, jit and tps. Continual problem solving is central to jit. Eliminating excess inventory makes problems immediately evident. Central to tps is employee learning and a continuing effort to produce products under ideal conditions. Small building but high levels of production. Subassemblies are transferred to the assembly line on a jit basis. High quality and low assembly time per vehicle. Good production systems require that managers address three issues that are pervasive and fundamental to operations management: eliminate waste, remove variability, and improve throughput. Jit is a philosophy of continuous and forced problem solving via a focus on throughput and reduced inventory. Tps emphasizes continuous improvement, respect for people, and standard work practices. Lean production supplies the customer with their exact wants when the customer wants it without waste. Tps emphasizes employee learning and empowerment in an assembly-line environment.